LVT PVC FLOORS 101

History

LVT / PVC FLOORS 101 is an overview and history of luxury vinyl. The world’s most versatile plastic had a rather humble beginning: A rubber scientist during the early 1920s stumbled onto a new material with fantastic properties during his search for a synthetic adhesive. Waldo Semon was intrigued with his finding, and experimented bymaking golf balls and shoe heels out of the versatile material called polyvinyl chloride, or PVC. Soon after his discovery, PVC-based products such as insulated wire, raincoats and shower curtains hit the market. As more uses for vinyl were discovered, industry developed more ways to produce and process the new plastic.

The 1930’s

Plants manufacturing PVC began to spring up during the ’30s to meet demand for the versatile material. Just a decade after its conception, PVC – commonly known as vinyl – was sought for a variety of industrial applications including gaskets and tubing.

The 1940’s

Joining industries across the nation during the ’40s, PVC manufacturers turned their attention to assisting the war effort. Vinyl-coated wire was widely used aboard U.S. military ships, replacing wire insulated with rubber. Vinyl manufacturers were working in high gear as World War II wound down, and they quickly found new markets for the durable plastic. Following the war, news of vinyl’s versatility and flame resistant properties spread, leading to dozens of commercial uses.

The 1950’s and 1960’s

Five companies were making PVC at the century’s midpoint, and innovative uses for vinyl continued to be found during the ’50s and ’60s.

A vinyl-based latex was used on boots, fabric coatings and inflatable structures, and methods for enhancing vinyl’s durability were refined,

opening the door to applications in the building trades.

The 1970’s

Vinyl products quickly became a staple of the construction industry; the plastic’s resistance to corrosion, light and chemicals made it ideal for building applications. PVC piping was soon transporting water to thousands of homes and industries, aided by improvements in the material’s resistance to extreme temperatures. Twenty companies were producing vinyl by 1980.

Today

Today, vinyl is the second largest-selling plastic in the world, and the industry employs more than 100,000 people in the United States

alone. Vinyl’s low cost, versatility and performance make it the material of choice for dozens of industries such as health care,

communications, aerospace, automotive, retailing, textiles and construction. Rigid as pipe or pliable as plastic wrap, vinyl is a leading

material of the 21st century.

What is Vinyl?

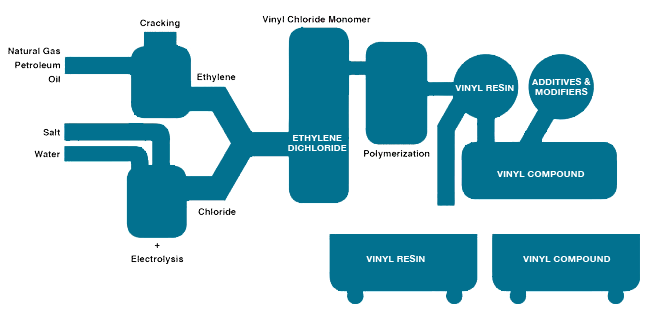

Vinyl (polyvinyl chloride or PVC), is the world’s most versatile plastic, used to make everything from food wrap to auto body parts. Vinyl is composed of two simple building blocks: chlorine, based on common salt, and ethylene, from crude oil.

The resulting compound, ethylene dichloride, is converted at very high temperatures to vinyl chloride monomer (VCM) gas. Through the

chemical reaction known as polymerization, VCM becomes a chemically stable powder, polyvinyl chloride resin.

Interesting Vinyl Statistics

• Vinyl is the second largest-selling plastic and the most versatile one.

• The vinyl resin industry has more than $4 billion in sales and employs more than 100,000 people.

• Vinyl is used in hundreds of consumer, industrial products.

• More than 14 billion pounds of vinyl are produced annually in North America.

Recycling

Even after a useful lifespan of decades, vinyl products can be recycled into new applications lasting decades more.

Manufacturing Scrap

A significant amount of vinyl scrap (coming from polymer manufacturers and plastic processors) is collected and recycled. Overall, more

than 99 percent of all manufactured vinyl compound ends up in a finished product, due to widespread post-industrial recycling.

How is Vinyl Made?

Complex Chemistry Based on Common Salt

Like all plastic materials, vinyl results from a series of processing steps that convert hydrocarbon-based raw materials (petroleum, natural

gas or coal) into unique synthetic products called polymers. The vinyl polymer is unusual, however, because it is based only in part on

hydrocarbon feedstock’s: ethylene obtained by processing, or cracking, natural gas or petroleum. The other half of the vinyl polymer is

based on the natural element chlorine.

Chlorine gives vinyl two advantages. First, chlorine is derived from brine — a solution of common salt and water, and a readily available,

inexpensive commodity. Thus, vinyl is less sensitive to fluctuations in the world oil market than are totally oil dependent polymers.

Second, chlorine has excellent inherent flame retardant properties. These properties are passed on directly to vinyl end-products, making

vinyl an excellent choice for applications such as electrical conduit and wiring that require high resistance to ignition and flame spread

From Monomer to Polymer Product.

Through a chemical reaction, ethylene and chlorine combine to form ethylene dichloride which, in turn, is transformed into a gas called

vinyl chloride monomer (VCM). A final step, called “polymerization,” converts the monomer into vinyl polymer, a fine-grained, white

powder or resin known as polyvinyl chloride (PVC), or simply “vinyl.”

Vinyl resin, however, is still one step away from being a usable material: it must be combined with selected chemical additives and

modifiers to achieve the various properties desired in vinyl end-products. Once these are added, the resulting material — vinyl compound

— can be converted into an almost limitless range of applications. (View the above diagram of the vinyl production process.)

This versatility is yet another reason why vinyl claims such a large share of the plastics market. It is the only plastic that can be made thin

and flexible enough for wall coverings, yet rigid and tough enough for siding on buildings. Depending on the additives and modifiers used,

vinyl compound can be used indoors or outside, be crystal clear or opaque, and matched to virtually any color in the rainbow.

PVC/VINYL

Vinyl – The material of choice.

As the material of choice for blood bags and tubing, vinyl helps to maintain the world’s blood supply and supports critical healthcare procedures such as dialysis. As a packaging material, vinyl helps to keep food safe and fresh during transportation and on store shelves, and it provides tamper resistant packaging for food, pharmaceuticals and other products. Because it will not rust or corrode, vinyl is widely used in water pipes to deliver clean, safe-to-drink water and in sewer pipes to ensure the integrity of wastewater handling systems. Vinyl’s resistance to breakdown under high electrical voltage and its ability to bend without cracking make it the leading material for wire and cable insulation. Vinyl’s toughness and durability make it the most widely used plastic for building and construction applications such as siding, windows, roofing, fencing, decking, wall coverings, wall protection and base, and floor covering.

What is vinyl and where does it come from?

Vinyl is essentially derived from two simple ingredients: fossil fuel and salt. Petroleum or natural gas is processed to make ethylene, and salt is subjected to electrolysis to separate out the natural element chlorine. Ethylene and chlorine are combined to produce ethylene dichloride (EDC), which is further processed into a gas called vinyl chloride monomer (VCM). In the next step, known as polymerization, the VCM molecule forms chains, converting the gas into a fine, white powder – vinyl resin – which becomes the basis for the final process, compounding. In compounding, vinyl resin may be blended with additives such as plasticizers for flexibility, stabilizers for durability and pigments for color. Through various plastics processing operations, manufacturers are able to offer versatile products with customized performance characteristics.

Because less than half of the vinyl polymer is from petroleum feedstock’s, and 99 percent of all vinyl produced ends up in a finished product due to manufacturing efficiencies across multiple business segments, it is one of the most energy-efficient plastics.

Is the process for manufacturing vinyl safe for workers, the environment and the surrounding community?

Yes. The vinyl production process is strictly regulated by federal, state and local governments, and is essentially enclosed and computer controlled, to safeguard the health of industry workers, people living near vinyl manufacturing facilities, and the environment. In addition, North American vinyl resin manufacturers have made a voluntary public commitment to achieve the goals of the chemical industry’s

Responsible Care® program (www.americanchemistry.com), one of the most comprehensive and conscientious standards of health, safety and environmental conduct created by any industry. Workplace exposures to VCM are limited by the U.S. Occupational Safety and Health

Administration (OSHA) to one part per million averaged over eight hours. This regulation was in response to a rare form of liver cancer found in highly exposed vinyl workers in the early 1970s. The vinyl manufacturing process was also reengineered in the 1970s to minimize worker exposure. No known case of this rare cancer has been identified in a U.S. vinyl production worker whose work history began after the stricter OSHA regulations and reengineered processing technology were introduced in the late 1970s.

The U.S. Environmental Protection Agency (EPA) regulates air and water emissions and solid waste disposal associated with the vinyl manufacturing process. The agency confirmed in 2002 that the vinyl industry was meeting the “maximum achievable control technology” standard for vinyl mandated in 1990 by the Clean Air Act. From 1987 to 2000, facilities operated by all U.S. producers reduced their reported releases of EDC and VCM by 95 percent and 74 percent, respectively. In reality, significant VCM emission reductions were made

long before 1987.

As in all industrial operations, the process of extracting chlorine from salt is not without risks, but the men and women who work in the high-tech facilities where chlorine is produced are highly trained to manage those risks. When combined with certain other substances, chlorine becomes beneficial and long lasting. For example, chlorine combined with sodium forms salt; chlorine with other chemicals forms 85 percent of all pharmaceuticals on the market; and chlorine with hydrogen and carbon forms polyvinyl chloride (PVC), or vinyl. The long service life of vinyl products translates into reduced need to dispose of and replace products. When vinyl is made into products such as commercial flooring, chlorine is in a very stable form, which is chemically different from the reactive elemental form. No chlorine is emitted from finished products. The chlorine component also inhibits the spread of a fire.

What is dioxin and where does it come from?

Dioxin is not produced intentionally; it can occur when anything containing chlorine burns. Because chlorine is so pervasive in the environment, dioxin is a byproduct of natural events like forest fires, lightning and volcanoes, as well as of manmade activity, such as burning wood and backyard trash, diesel vehicle emissions and various manufacturing processes.

In the past 30 years, dioxin levels in the environment have sharply and steadily declined while production of vinyl has more than tripled. EPA attributes the dramatic declines in dioxin emissions to regulations and voluntary industry actions. Incinerators are a good case in point. Studies consistently show that dioxin emissions from waste incinerators are primarily the result of how things are burned, not what is burned. Regulations have improved how incinerators operate. EPA has stated that its “best estimates of emissions from sources that can be reasonably quantified indicate that dioxin emissions in the United States decreased about 80 percent between 1987 and 1995, primarily due to reductions in air emissions from municipal and medical incinerators, and substantial further declines continue to be documented.” By 2004, EPA estimates dioxin emissions will be down more than 90 percent from 1987 levels.

Emissions from vinyl production are a small fraction of total emissions. Sources of greater dioxin emissions than vinyl manufacturing include open burning (the largest source), fireplaces, coal-burning utilities, vehicle emissions and metal smelting.

Are the plasticizers used to make floors containing vinyl a health issue?

Independent scientists, international governmental bodies and phthalate producers have conducted extensive studies on the safety of phthalates – the plasticizers used to make vinyl flexible. In more than 40 years of study and use, phthalates have never been shown to cause harm to humans from their normal, intended use. Phthalates are tightly bound in the structure of the vinyl and have very low volatility, which means that they do not tend to evaporate.

Thus, they would be an unlikely contributor to “sick building syndrome.“ Asthma is a growing concern today, and extensive research is being conducted on its possible causes. The Institute of Medicine (IOM) of the National Academy of Sciences has reviewed the research on possible sources (including phthalates), and phthalate plasticizers are not on IOM’s list of more than a dozen chemical and biological agents to which exposure was found to be associated with asthma.

EPA does not list phthalates as persistent, bioaccumulative and toxic materials. Phthalate-plasticized vinyl is the material of choice for many medical products – such as blood bags and tubing – regulated by the U.S. Food and Drug Administration.

Do floors containing vinyl have any impact on indoor air quality?

Most architects, designers and builders agree that the air quality inside a building depends on a number of factors, including how a building is designed, built and maintained; the construction materials, furnishings and cleaning materials used in the building; the heating/ventilating/air conditioning (HVAC) system; and the behavior of occupants.

Products emitting low levels of VOCs (volatile organic compounds) should be considered when selecting interior products. Any VOCs that are emitted from floors containing vinyl are dissipated quickly through normal ventilation. Vinyl products will not adversely impact indoor air quality when installed according to manufacturers’ recommended procedures.

The RFCI FloorScore® (provide link to FloorScore) Indoor Air Quality Certification Program has established indoor air quality standards for hard surface flooring products. Products with emissions below the program’s established emission criteria are considered low emitting products and receive FloorScore® certification.

A significant indoor air quality advantage of vinyl flooring is that it is impervious to moisture, so spills will not penetrate surfaces where such moisture could lead to microbial growth. Also, a study published in the American Journal of Infection Control (August 2000) supports the use of easy-to-clean surfaces such as vinyl in healthcare settings as a way of controlling pathogens and promoting a sterile environment. This is one of several reasons why vinyl flooring is widely accepted and specified by hospital and healthcare designers.

How do floors containing vinyl behave in accidental fires? Are any potentially harmful gases released when floors containing vinyl burn?

Vinyl has excellent fire performance qualities. Vinyl building products are based on a naturally fire retardant polymer, and some flexible products like vinyl flooring and carpet backing contain non-combustible additives and fillers such as calcium carbonate that further improve the fire performance of the material. Vinyl is one of the few materials meeting the stringent requirements of the National Electrical Code of the National Fire Protection

Association for insulating electrical cords and wires and data transmission cables, even in plenum applications. In addition, floors containing vinyl meet the requirements of relevant national building codes. Carpets are required to pass the Federal Flammability test

DOC FF 1-70 which ensures they will not propagate the spread of flame in the early stages of a fire.

The vinyl industry and third-party organizations have conducted research on the combustion toxicity of vinyl products. The contribution of the combustion products from floors containing vinyl to the overall toxic threat of fires containing many types of combustibles is not significant. The Pittsburgh Protocol is a standard test method for evaluating the combustion toxicity of floor covering products. In this test, vinyl flooring is no more toxic than when burning than red oak wood.

Fire scientists recognize that the largest hazard in a fire is carbon monoxide (CO), an odorless asphyxiant gas produced in abundance by all organic materials, natural and synthetic. The mix of gases produced when vinyl products burn is very similar to those of other common materials, including wood and fabric.

Hydrogen chloride (HCl), an irritant gas having a pungent odor, is produced when vinyl burns and is detectable in very small quantities long before it reaches a dangerous concentration. An argument can be made that HCl can act as an early warning that there is a fire, and alert occupants to evacuate. HCl is unique in that its concentration in the air decreases rapidly when it reacts with humidity and most construction surfaces, like cement block, ceiling tile and gypsum board.

The U.S. fire death rate is decreasing, dropping from a rate of 76 per million in the 1940s to 15 per million in the 1990s (by which time vinyl and other plastics had achieved significant market share in numerous applications). This downward trend can be attributed in large part to improved building codes, as well as the broader use of sprinkler systems and smoke detectors. However, the increased use of more fireretardant materials – like vinyl – deserves part of the credit for this improvement.

Are there any restrictions to disposing of vinyl in landfills?

Typically no, for vinyl flooring manufactured after 1985. In fact, landfills are often lined with vinyl membranes to protect groundwater. This is because the vinyl sheets are long lasting and virtually inert. Flooring, including sheet vinyl, vinyl or asphalt floor tiles and any associated paper-like underlayment backing, mastic, and asphaltic (cutback) adhesive manufactured prior to 1985 may contain asbestos and can be sent to approved landfills following the Recommended Work Practices for the Removal of Resilient Floor Coverings. (include link to Recommended Work Practices)

Can commercial floors containing vinyl be recycled? Are they currently being recycled?

As a thermoplastic, vinyl is an inherently recyclable material; when floors containing vinyl are produced, manufacturing scraps are routinely recycled directly back into the process. A number of manufacturers have “take back” programs where previously installed products such as Vinyl Composition Tile are recycled back into resilient flooring. As with any building product, the key to effective post consumer vinyl recycling is to find a way to collect, separate and transport materials for recycling cost effectively at the end of their useful life.

What do life cycle studies show about vinyl?

Since the late 1980s, at least 26 life cycle evaluations have been published on vinyl building products, many of them comparing vinyl products to similar products made of other materials. In some cases vinyl has a lighter impact on the environment, in others, it doesn’t. However, vinyl products generally have been found to perform favorably in terms of energy efficiency, thermal-insulating value, low contribution to greenhouse gases and product durability, which means using fewer resources.

The Natural Step (TNS), a highly regarded international organization that uses a science-based, systems framework to help organizations and communities understand and move towards sustainability, evaluated vinyl from its salt and natural gas beginnings through to finished products in the waste stream. In a cover letter accompanying the report, Jonathon Porritt, TNS Chairman, wrote, “It serves little purpose arguing for the elimination of PVC without first assessing the degree to which any substitutes would have a lower ‘sustainability footprint.’ PVC may or may not have a place in a genuinely sustainable future (depending on whether or not it can meet the challenges outlined in our Evaluation), but exactly the same questions must be asked of all materials, be they man-made or natural, before leaping to what are often ill-judged and unscientific conclusions.”A life cycle analysis (LCA) conducted for the United Kingdom’s Department of the Environment, Transport and the Regions showed that vinyl is the best material for some uses and that the differences between the alternatives are small when environmental impacts are considered from the extraction of raw materials to final disposal.

Has vinyl’s environmental performance been endorsed by any international environmental, scientific or government organizations?

When vinyl is evaluated according to unbiased scientific principles, it is often endorsed as an environmentally safe and beneficial material. A few recent examples:

• CSIRO, Australia’s premier scientific organization, completed a multi-year study in 1998 which determined that vinyl performs as well as or better than alternative building materials environmentally. The German Council of Environmental Advisors, which advises the German government on environmental issues, issued an endorsement of vinyl, revoking its earlier recommendation that substitutes be found. In the early 1990s, the German cities of Berlin, Bielefeld, Chemnitz, Kassel and Osnabruch, the regions of Herzogturn Lauenburg and Westerwald as well as the states of Hessen, Mecklenburg- Vorpommern and Thuringen withdrew their anti-PVC resolutions either fully or in part.

• Naturvardsverket, Sweden’s environmental protection agency, and Kemikalieinspektionen, its chemicals inspectorate, have reviewed vinyl’s environmental performance in the areas of waste management and additives. In 1998, the Swedish government gave approval for continuing the sustainable development of vinyl, focusing specifically on substitution for some additives and increased recycling.

• In our own country, the U.S. EPA has recognized many vinyl roofing and windows manufacturers as eligible for their ENERGY STAR® designation for those products that meet agreed-upon energy-efficient criteria.

Why have some companies chosen to replace vinyl with other materials?

Vinyl competes with many materials on a cost/performance basis. For every company that has decided not to use vinyl, numerous

others select it as a material of choice – particularly in commercial flooring – because of its proven long-term durability, imperviousness to moisture, low maintenance requirements, cost effectiveness and strong environmental and safety characteristics.

What is the outlook for vinyl?

Vinyl has grown to become the second largest plastic material sold globally and consistently grows year after year in the world market.

According to Chemical Market Associates, Inc., North American demand for vinyl should increase more than 3 percent yearly through

2010.

We have done our research for you. To learn more about LVT / PVC Flooring visit or research the following resources.

References

1. “Post-Consumer and Post-Industrial Vinyl Reclaim: Material Flow and Uses in North America,” Principia Partners, July 1999.

2. Presentation by Dr. Marc Boeckx, Tessenderlo Group, the 30th Congress on Occupational and Environmental Health in the Chemical Industry (Medichem 2002),

Baltimore, Maryland, Oct. 26-28, 2002.

3. H. Gregor Rigo, A. John Handler, W. Steven Laurier, “The Relationship Between Chlorine In Waste Streams and Dioxin Emissions From Waste Combustor Stacks,” The American Society of Mechanical Engineers, 1995.

4. “Dioxin: Summary of the Dioxin Reassessment Science,” Information Sheet 1, U.S. EPA, June 12, 2000.

5. “Clearing the Air: Asthma and Indoor Air Exposures,” Institute of Medicine Committee on the Assessment of Asthma and Indoor Air, National Academy of Sciences, 2000.

6. Test for Combustion Product Toxicity, University of Pittsburgh Graduate School of Public Health, Oct. 30, 2002.

7. W.A. Burgess, R.D. Treitman and A. Gold, “Air Contaminants in Structural Firefighting,” N.F.P.C.A. Project 7X008, Harvard School of Public Health, 1979.

8. A.F. Grand, H.L. Kaplan and G.H. Lee, “Investigation of Combustion Atmospheres in Real Fires,” U.S.F.A. Project 80027, Southwest Research Institute, 1981.

9. J.J. Beitel, C.A. Bertelo, W.F. Carroll, R.A. Gardner, A.F. Grand, M.M. Hirschler and G.F. Smith, “Hydrogen chloride transport and decay in a large apparatus. I. Decomposition of poly(vinyl chloride) wire insulation in a plenum by current overload,” J. Fire Sciences, 4, 1986.

10. C.A. Bertelo, W.F. Carroll, M.M. Hirschler and G.F. Smith, “Thermal decomposition of poly(vinyl chloride). Kinetics of generation and decay of hydrogen chloride in

large and small systems and the effect of humidity,” in “Fire Safety Science, Proceedings of the 1st International Symposium,” C.E. Grant and P.J. Pagni, editors, Hemisphere, Washington, 1986.

11. J.J. Beitel, C.A. Bertelo, W.F. Carroll, R.A. Gardner, A.F. Grand, M.M. Hirschler and G.F. Smith, “Hydrogen chloride transport and decay in a large apparatus: II. Variables affecting hydrogen chloride decay,” J. Fire Sciences, 5, 1987.

12. F.M. Galloway, M.M. Hirschler and G.F. Smith, “Model for the generation of hydrogen chloride from the combustion of poly(vinyl chloride) under conditions of forcefully minimized decay,” Eur. Polymer J., 25, 1989.

13. F.M. Galloway, M.M. Hirschler and G.F. Smith, “Surface parameters from small scale experiments used for measuring HCl transport and decay in fire atmospheres,”

Fire and Materials, 15, 1992.14. “PVC: An Evaluation Using the Natural Step Framework,” The Natural Step, Cheltenham, Gloucestershire, UK, July 2000.

15. “Life Cycle Assessment of Polyvinyl Chloride and Alternatives,” Entec UK Limited and Ecobalance UK, Department of the Environment, Transport and the Regions: London (now the Department for Environment Food and Rural Affairs), February 2001.

16. “Environmental Aspects of the Use of PVC in Building Products, Second Edition,” a study carried out for the Plastics and Chemicals Industries Association, Inc., CSIRO Molecular Science, June 1998.

17. “Disposal of PVC Waste – Report on a Government Assignment,” Report 4594, Naturvardsverket, and “Additives in PVC; Marking of PVC – Report on Completion of a Government Task,” Kemikalieinspektionen, June 1996.

LVT PVC FLOORS 101 – Luxury Vinyl Floors 101 by Hallmark Luxury Vinyl is education information on the process of making vinyl for floors.

Simply Beautiful

Simply Better

Simply Hallmark