CARB IIBianca Ruddy2017-09-27T16:22:46-07:00

CARB II | Hallmark Floors

Breathe easy with Hallmark Floors

Hallmark Exceeds CARB II Certification Standards

FAQ ABOUT HALLMARK FLOORS and CARB II

Is Hallmark CARB II compliant for formaldehyde emissions?

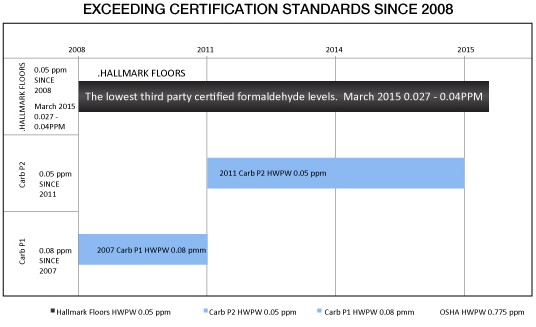

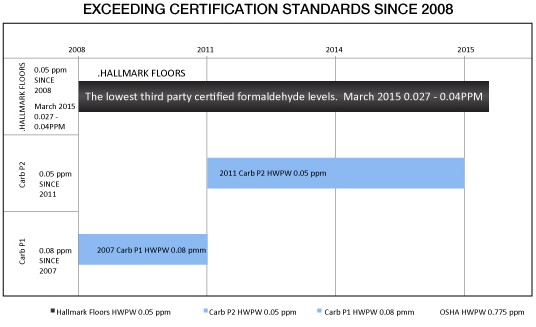

Hallmark Floors takes pride in the fact that from our inception, indoor air quality has been a very high priority. Our manufacturing process is closely monitored and third party certified. We pride ourselves as being a cutting edge company when it comes to having obtained world class, low-formaldehyde emissions. In fact, Hallmark has been producing product that met the CARB II standards in 2008, a year prior to the CARB I standard and three years prior to the CARB II standards being developed and implemented.

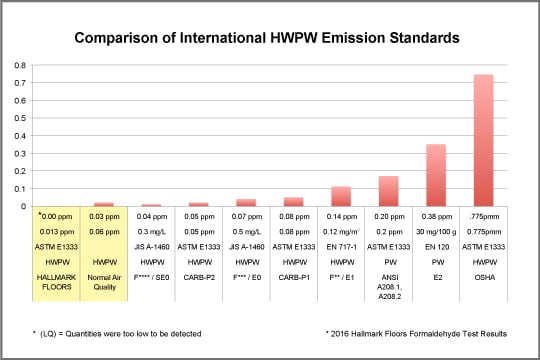

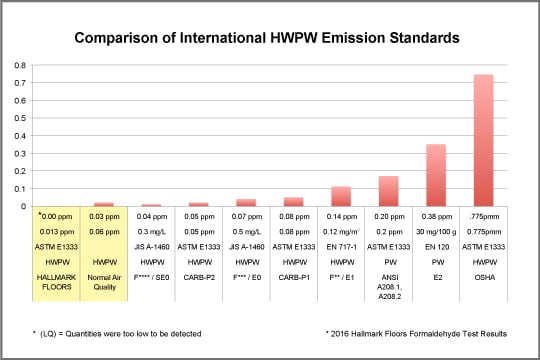

OSHA – the US Occupational Safety and Health Administration guidelines allowed for more emissions than were permitted in Europe and Japan. Hallmark felt the most responsible thing to do for our customers was to emulate the more stringent international standards, E-0.

On January 1, 2009 the State of California (California Air Resource Board) implemented the CARB I standard of 0.08ppm (parts per million emission) for engineered hardwood flooring and hardwood plywood.

On January 1, 2011 CARB II was fully implemented at a maximum emission rate of 0.05ppm, which is lower than the International Standard E-0. CARB II is 15.5 times lower than the federal guidelines as determined by OSHA (0.775). CARB II is much closer to the rate of normal air quality ranging from 0.03ppm to 0.08ppm. Formaldehyde at these levels is naturally occurring, with higher levels typically in urban areas. To be completely Formaldehyde free is impossible given that plant matter naturally contains these trace amounts. The real point of CARB II is to ensure that engineered wood products are not pushing levels past the acceptable standards of nature.

Independent Third Party Certified.

Hallmark Complies with CARB II Certification Standards.

1a. Certificate March, 2017 .pdf

2a. Certificate March, 2017 .pdf

Exceeding Certification Standards Since 2008

FAQ ON CARB II

Carb II is the California Air Resource Board’s newest emission standard for formaldehyde exposure in composite wood products. The first phase (CARB I) took effect on January 1, 2009. Shortly after the induction of CARB I, the California Air Resource Board decided to make emission standards more strict in the state. Beginning January 1, 2011, CARB II took effect. Hardwood plywood (HWPW) now has a 0.05-ppm maximum, particleboard (PB) has a 0.09-ppm maximum, and medium density fiberboard (MDF) now has a 0.11-ppm maximum. As of today, only Japan, Europe, and California have their own emission laws, but the rest of the United States is expected to adopt the CARB II standards sometime in 2015.

Information from http://www.ewp.asn.au/library/downloads/ewpaa_formaldehyde_emmisions.pdf Formaldehyde is a colorless strong smelling gas. Formaldehyde occurs naturally in the environment and is emitted by processes such as combustion, decay and is emitted naturally by all timber species. Formaldehyde is present in exhaust fumes, wood smoke, tobacco smoke and is produced by domestic appliances such as combustion heaters. Formaldehyde is present in the air that we breathe at natural background levels of about 0.03 parts per million (ppm) with recent studies showing formaldehyde concentrations often up to 0.08ppm in outdoor urban air. Formaldehyde is industrially significant with the downstream use of formaldehyde-based inputs contributing approximately 8% to US gross domestic product. Formaldehyde is used as an ingredient in synthetic resins, industrial chemicals, preservatives, and in the production of paper, textiles, cosmetics, disinfectants, medicines, paints, varnishes and lubricants.

You can check with your local supplier and find out what a companies policy is as to their compliance with the CARB II standards. All flooring sold in California is legally obligated to follow such standards. Though it is expected to become a nationwide standard in 2015, no other state in the United States is legally obligated to follow the CARB II standards. There is also formaldehyde-testing kits that are available for purchase online through Amazon.com.

As of today, there is no national law in place against these chemical emissions. In the United States, only California has the law of CARB II emission control laws. If someone bought flooring today from any other state, a company could sell that person a product with as much formaldehyde as they wanted. However, the United States is expected to adopt the laws made by California to make the rest of the nation CARB II compliant. This law is expected to become nationally recognized by 2015.

Fortunately, acceptable formaldehyde emission levels from wood panel products are continuously dropping. Some reasons for these levels to be lowered are public awareness, which creates a greater demand for non-hazardous products, as well as things such as government regulations. The International Agency for Research on Cancer, and the National Toxicology Program now recognize formaldehyde as a carcinogen. This has made the public more concerned on the topic, and has also gotten reactions by worker and consumer associations, environmental organizations, authorities, and the industry itself. Generally, all flooring manufactured in North America abides by the American National Standard for Particleboard (ANSI A208.1). This is the voluntary standard. In North America, the allowed formaldehyde emission levels are 0.20 ppm for particleboard. Flooring that is manufactured in Europe abides by the European E1 standard, which is 0.14 ppm. Flooring that is manufactured in Asia and imported to North America abide by the European E2 standard, which is 0.32 ppm. On April 26, 2007, the California Air Resources Board (CARB) approved an airborne toxic control measure. This control measure reduced acceptable formaldehyde emissions from hardwood plywood (HWPW), particleboard (PB), and medium density fiberboard (MDF). The CARB standard is for indoor products in the state of California, but will be the standard for the rest of North America, and is recognized around the world. The CARB rule was put into place in two phases. CARB I was implemented January 1, 2009. These standards for the allowed formaldehyde emissions were 0.08 ppm for HWPW, 0.18 ppm for PB, and 0.21 ppm for MDF. Two years after CARB I was introduced, CARB II was set and allowed emission levels were lowered. The new standards were set at 0.05 ppm for HWPW, 0.09 ppm for PB, and 0.11 ppm for MDF. CARB II is the law for formaldehyde emissions in California, but has yet to be implemented across the rest of the United States. The rest of the country is expected to abide by the CARB II standards in 2015.

Hallmark Floors has taken pride since the beginning of development to make sure all areas of production are closely monitored and in compliance with the CARB II standard. Hallmark Floors makes their glues in Japan, which was the first country to set formaldehyde standards. Hallmark Floors has actually been CARB II compliant years before the standard was put in place. Hallmark Floors has always believed in not only creating a quality product, but also an environmentally responsible product. Another way that Hallmark Floors ensures a reduction in the use of formaldehyde in their products is the exclusive use of hardwood plywood (HWPW). With maximum emission levels being at 0.05 ppm for HWPW, it is the lowest amount of formaldehyde emission allowed according to the CARB II standard. HWPW also requires the least amount of glue when being produced, so not only are the emission levels incredible low, but the amount of glue itself is lower than other composite woods.

Comparison of International HWPW Emissions Standards

Definitions:

Standards

CARB-P1: California Air Resources Board Phase 1 emission standard (Allow

sell-through date for PB & MDF is unitil Dec 31, 2011)

CARB-P2: California Air Resources Board Phase 2 emission standard

(Enforcement date for PB & MDF is Jan 01, 2012)

ANSI A208.1 & 2: North America voluntary standards ANSI A208.1-

2009 Particleboard & ANSI A208.2-2009 MDF (include most of

industrial particle boards and MDF)

E2: European E2 emission standard (Most import products from Asia

are E2 or worse)

E1: European E1 emission standard

E0: European E0 emission standard

SE0: European Super E0 emission standard

F**: Japanese F-Star2 emission standard

F***: Japanese F-Star3 emission standard

F****: Japanese F-Star4 emission standard

JIS: Japanese Industrial Standard

Products

HWPW: – Hardwood / Plywood

PW: – Industrial plywood

PB: – Particleboard

MDF: – Medium density fiberboard

ppm: – Parts per million

Yes! Hallmark has been CARB II compliant years before the CARB II standard was put into place in 2011. Hallmark Floors has been proactive in making a great product safe for its users.

Use Hallmark 1 Primer to consolidate the gypcrete allowing for a smooth surface to accept Hallmark 3 Adhesive.

No. Many adhesive removers contain solvents that would leave a residue on the surface of the subfloor. This residue can react negatively with the new adhesive and bleed through the new floor covering.

The properties in formaldehyde are exceptional and are not easily replaceable. Replacing formaldehyde also makes a product more expensive to produce, which will drive up costs not only for production, but also for a potential end user.

No. Any existing resilient flooring must be removed before any new flooring is installed.

We are Carb II compliant. Formaldehyde exists naturally in many plant fibers. Formaldehyde has been found to be an excellent binding agent in the glues that hold the different layers of plywood, fiber type panels, strand board and engineered hardwood floors together. Low-emitting glue systems are formulated to encapsulate the formaldehyde to reduce the emissions they may give off. CARB II requires that formaldehyde emissions are reduced to a level more compatible with what would be found in natural outdoor air.

When using Hallmark Floors, a person is no more susceptible to allergic reactions than any other floor. The levels of formaldehyde in Hallmark’s products are so low that it is not possible to get a reaction from the formaldehyde content itself. It is easier to argue that someone’s allergic responses would be lower if they had Hallmark Floors installed in their home. A hard surface is always better for someone’s allergies than other floors such as carpet. Carpet soaks in dust particles, pollen, and other allergens that can become stuck into the fibers, while a hardwood or luxury vinyl keep these allergens on top of the floor, which are easily cleaned from the surface.

Hallmark Floors has four collections of luxury vinyl that use Nano control technology in their finish. The anti-microbial characteristics of this finish make the finish kill viruses and bacteria as they come in contact with the floor’s surface. The titanium dioxide additive in the finish reacts to light, which makes this possible without the use of harsh chemicals.

Sustainability | Hallmark Floors